ince 2013, Scala Filtration has been delivering quality compressed air purification equipment and laboratory liquid nitrogen generators around the world.

To lean more about latest technology and solution to compressed air treatment and liquid nitrogen generation,please contact us immediately.

Compressed Air Treatment & Liquid Nitrogen Generator

265CFM oil removal coalescing filter for compressed air system

| Categories | Thread Coalescing Filter |

|---|---|

| Trademark/Brand | SCALA |

| Model | F0265 |

| Flow Rate | 265CFM( 7.5m3/min) |

| Max Pressure | 16bar |

| Connection | 1-1/2'' |

| Filtration grade | H |

| Particulate removal down to | 0.01micro |

| Oil removal down to | 0.01ppm(w) |

| Optional | Inner automatic drain |

| Optional Accessories | Differential pressure gauge |

| Unit Price | US $ 130-230 / piece |

| FOB port | Shanghai |

| Terms of Payment | T/T, Western Union |

| Update Time | Nov 5,2025 |

Compressed air contains harmful solid, liquid and vaporous contaminants that can damage pneumatic equipment, control and instruments. Removal of these contaminants is necessary to sustain equipment life and continue efficient production operation. Rust, scale and decay within compressed air system piping, and ambient air that contains gaseous and corrosive substances are common factor that contribute to the damaging effect of compressed air.

Compressed air purification equipment must deliver high quality air with the lowest cost of operation.

Low pressure drop- Energy Efficient

EU made inner drain,differential pressure gauge

Inner threaded installation,easy to replace the element.

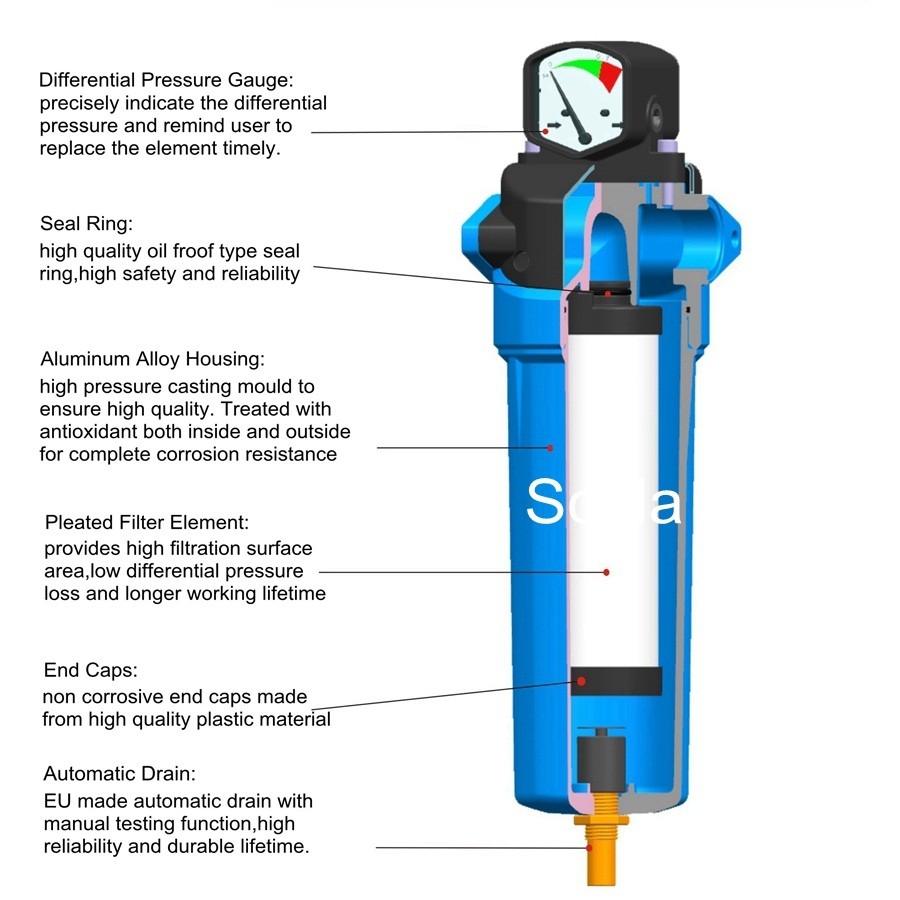

Pleated element, low pressure drop ,large filtration area.

Stainless steel and aluminum alloy hosing features high cooling effect.

Suitable for all compressed air application and all compressor type

Suitable for mineral and synthetic oil and oil free application

Silicon free ,safe for painting and surface coating applications

Electrophoresis treatment eliminating corrosion on internal and external head and bowl surfaces.

Scala elements are manufactured for lowest pressure drop and in accordance with International Standard for compressed air quality ISO8573.1:2001

SCALA filter is equipped with differential pressure gauge which can precisely indicate the differential pressure and remind user to replace the element timely.

EU made automatic drain with manual testing function. It has high reliability and durable lifetime. If the condensate water is not discharged timely, the oil and water may be brought into the downstream pipeline to cause contamination.

SCALA's high efficiency filter element has the following advantages:

1. Deep Bed Pleating

Pleated filter elements provides a greater filtration volume than non-pleated.

The large surface area and the low velocity, increase the space for holding contaminants,which reduce the differential pressure cased by retention of solid particles. The service life increase with a result of lower running cost.

2. Adopted with stainless steel diamond mesh which has larger filtration area and less pressure resistance compared to circular hole mesh.

3. Adopted with heat and corrosion resistant polyester wadding instead of traditional form. Form tears under high operational temperature causing the broken pieces to be carried over down stream.

4. No Pull rod design, saving installation space and very easy to change the element.

Elbow piping from air inlet to element which has smaller pressure drop compared to right angle piping. Antioxidative and painting treatment on housing features high corrosion resistance.

Air leakage can cause energy loss,many micro leakages are not easily found, SCALA filters are 100% leakage tested.

| TECHNICAL DATA | |||||||||

| Filter Model | Port Size | Max. Pressure | Flow Rate (7bar,20 ℃) | Dimensions(mm) | Element Model | ||||

| inch | bar | Nm3/min | cfm | A | B | C | D | ||

| F0020* | 1/2’’ | 16 | 0.57 | 20 | 95 | 220 | 197 | 95 | 0020E* |

| F0045* | 1/2'' | 16 | 1.3 | 45 | 95 | 220 | 197 | 110 | 0045E* |

| F0070* | 3/4'' | 16 | 2 | 70 | 95 | 280 | 257 | 145 | 0070E* |

| F0100* | 3/4'' | 16 | 2.8 | 100 | 95 | 280 | 257 | 175 | 0100E* |

| F0125* | 1'' | 16 | 3.5 | 125 | 125 | 315 | 285 | 155 | 0125E* |

| F0180* | 1'' | 16 | 5.1 | 180 | 125 | 315 | 285 | 185 | 0180E* |

| F0265* | 1-1/2'' | 16 | 7.5 | 265 | 125 | 397 | 367 | 200 | 0265E* |

| F0370* | 1-1/2'' | 16 | 10.5 | 370 | 125 | 397 | 367 | 200 | 0370E* |

| F0515* | 2'' | 16 | 14.6 | 515 | 170 | 520 | 478 | 300 | 0515E* |

| F0745* | 2'' | 16 | 21.1 | 745 | 170 | 700 | 658 | 300 | 0745E* |

| F1060* | 2-1/2’’ | 16 | 30 | 1060 | 200 | 995 | 938 | 300 | 1060E* |

| F1280* | 3’’ | 16 | 36.3 | 1280 | 200 | 995 | 938 | 300 | 1280E* |

| F1650* | 3’’ | 16 | 46.7 | 1650 | 200 | 995 | 938 | 300 | 1650E* |

Filtration Grade

Separator, filter, removal large amount of solid or liquid rust, abrasion particles.

Grade M- 1 micro,0.1mg/m3 general purpose coalescing filter

Removal of medium amounts of solid or liquid, fine contaminants, fine dust particle, small droplets and aerosols

Grade H- 0.01micro,0.01mg/m3 high efficiency colaescing filter

Removal of small amounts of solid or liquid,fine contaminants,fine dust particle,oil mist and aerosol

Removal of small amounts of gaseous, contaminants in particular oil vapor.

Pressure-bar g | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

Factor | 0.5 | 0.63 | 0.75 | 0.88 | 1 | 1.13 | 1.25 | 1.38 | 1.5 | 1.63 | 1.75 | 1.88 | 2 | 2.13 |

FAQ

What’s your delivery time?

We keeps some stock for standard filters,normally delivery time is within one or two week.

Can you paint OEM color ?

Yes,you need to tell us your color code.The MOQ for OEM color is 100pcs for a mixed order.

Can you make other connections?

We make BSP and NPT for different market,other non-standard connection size can be further discussed.

Can you send a sample for testing ?

Sample can be ready within 3 to 10 days after receiving the payment.

What’s your payment terms?

We accept 30% by T/T in advance,70% by T/T before shipment etc.

Any question ? Contact Us

Contact person: Sean Wu

Tel: 0086-571-86176836

Fax: 0086-571-56035108

Mobile phone: 0086-13758206140

Skype: seanwu1984

Whatsapp: 0086-13758206140

Email: sales(at)scala-filtration.com

- Loading...

- Tel

- *Title

- *Content

- laboratory liquid nitrogen generator delivered to Tibet College of Agriculture and Animal HusbandryRecently, our company successfully supplied a self-developed laboratory liquid nitrogen generator for the Plant College of Tibet University of Agriculture and Animal Husbandry, with a liquid nitrogen output of > 20 liters per day.

- Hangzhou Scala officially launched silent laboratory liquid nitrogen generatorAs a professional laboratory liquid nitrogen solution provider, Hangzhou Scala recently officially launched a new integrated liquid nitrogen generator, the equipment is small, low noise, high degree of automation, easy to use and maintain. After more than a year of internal testing, all parameters have met the expected requirements.