Hangzhou ScalaFiltration Technology Co.,Ltd

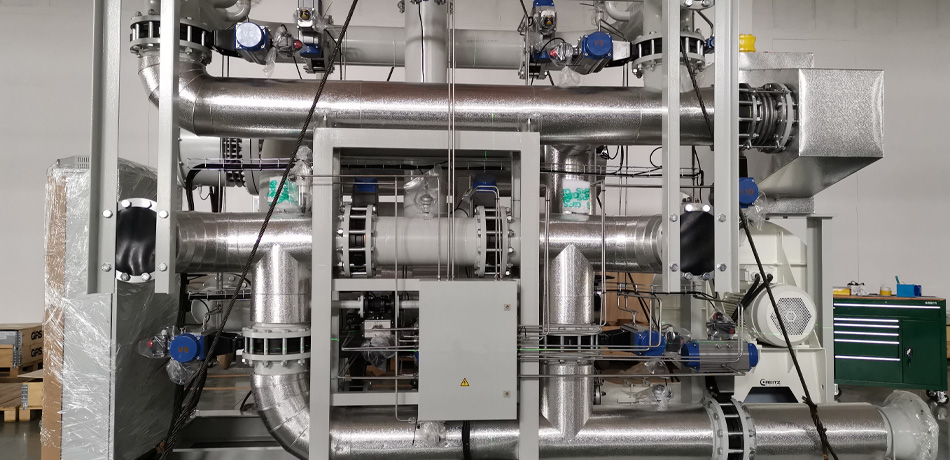

Since 2013, Scala Filtration has been delivering quality compressed air purification equipment and laboratory liquid nitrogen generators around the world.

The compressed air dryers and filters are wildely used in production line where use dryer and clean compressed air. Liquid nitrogen generators are mainly used in sample storage,animal husbandry,IVF,NMR, hospital,university and research institutes etc.